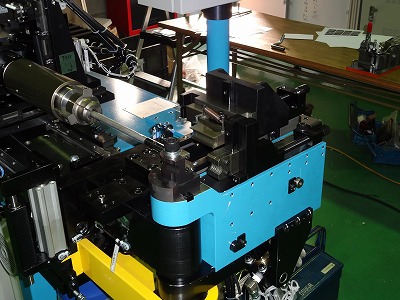

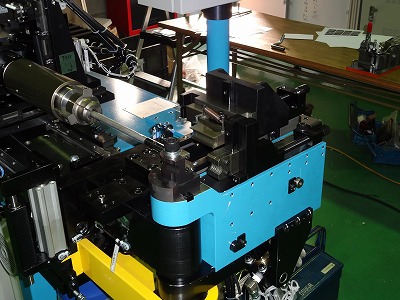

主な特長

- MINI型~30型までラインナップ

- オプションでプレッシャーブースター、手元芯金装置にも対応

- スペースに応じて送り長変更も可能(製作実績MAX3000)

- 他社製金型搭載も柔軟に対応させていただきます

- 大きさは20型でよいが曲げのトルク、プレッシャーの推力だけ30型クラスが欲しい!といった細かなオーダーにも対応しております

制御装置:三菱製シーケンサーQシリーズ+GOT表示機

2種R式(1種R式も製作可)

マンドレル装置、マンドレル給油装置や手元芯金装置、ワイパーダイ取付にもオプションで対応可